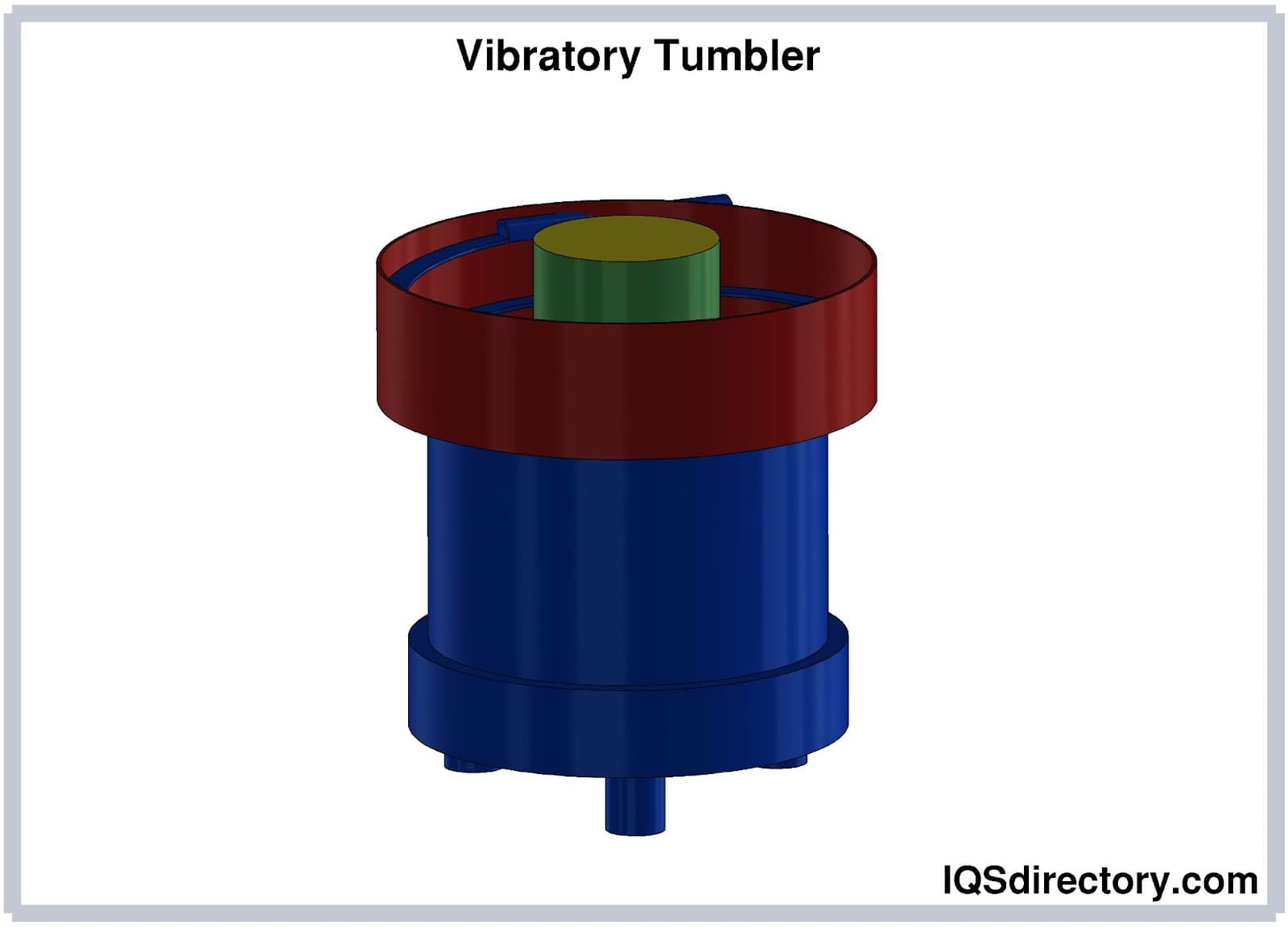

A vibratory tumbler is a piece of equipment used in the process of vibratory finishing. Vibratory finishing is one of the most used procedures when performing mass finishing. Read More…

OTEC Precision Finish, Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Raytech Industries specializes in the manufacturing and sales of high-quality metal finishing equipment. Raytech offers vibratory tumblers, magnetic finishers, parts separators, finishing compounds, and finishing media. Raytech is an American-owned company and has been serving the needs of the industry since 1958 through our quality and innovative products.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

The Deburring Company is committed to providing superior service by using today's innovations to produce the highest quality product in a safe and efficient environment. The Deburring Company conforms to the ISO 9001-2000 requirements and implements continuous improvement efforts to ensure customer satisfaction.

More Vibratory Tumbler Manufacturers

How Vibratory Tumblers Work

To begin the process with a vibratory tumbler, all unfinished parts and workpieces are placed into a tub. This tub is full of specially shaped pellets, and a vibration force is applied to all the contents inside the tub.

The motor inside the vibratory tumbler applies substantial vibrational force. A special chemical is usually poured and maintained inside the tub to aid in finishing.

The result of the workpieces grinding and rubbing against each other from the vibrational force is an end product of neatly polished workpieces.

Types of Vibratory Tumblers

The different types of vibratory tumblers include:

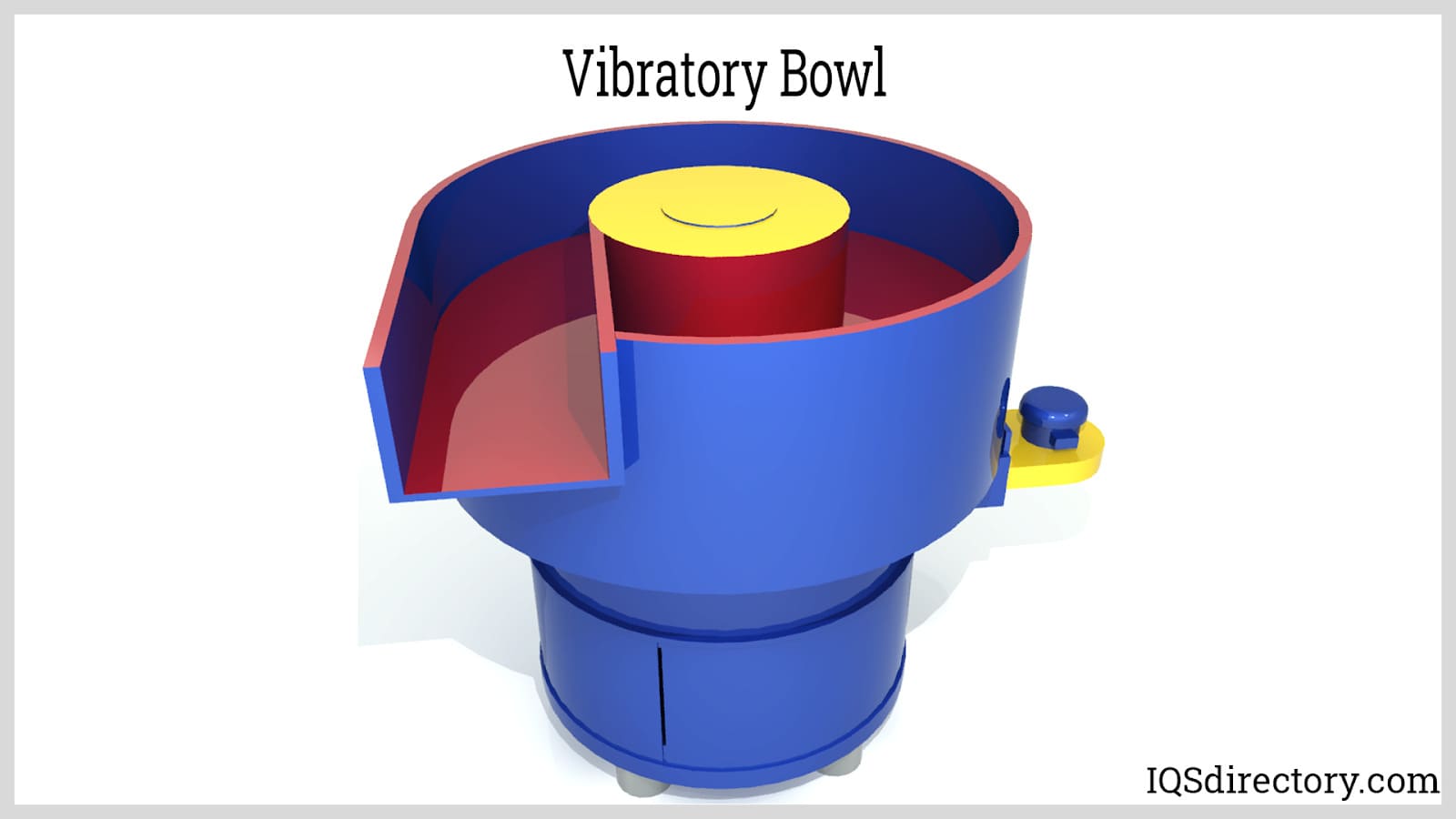

Vibratory Bowl

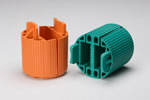

The vibratory bowl is lined with polyurethane. Of all the equipment used for vibratory finishing, it is the one with the simplest configuration. One outstanding advantage of the polyurethane lining is that it minimizes the frictional coefficient between the media and the bowl.

This will protect them from wear over time. Polyurethane also comprises dividers, which can be adjusted in order to perform specific processes for unique parts on their own. This reduces friction from part to part. Big and small batches are all supported by vibratory bowls.

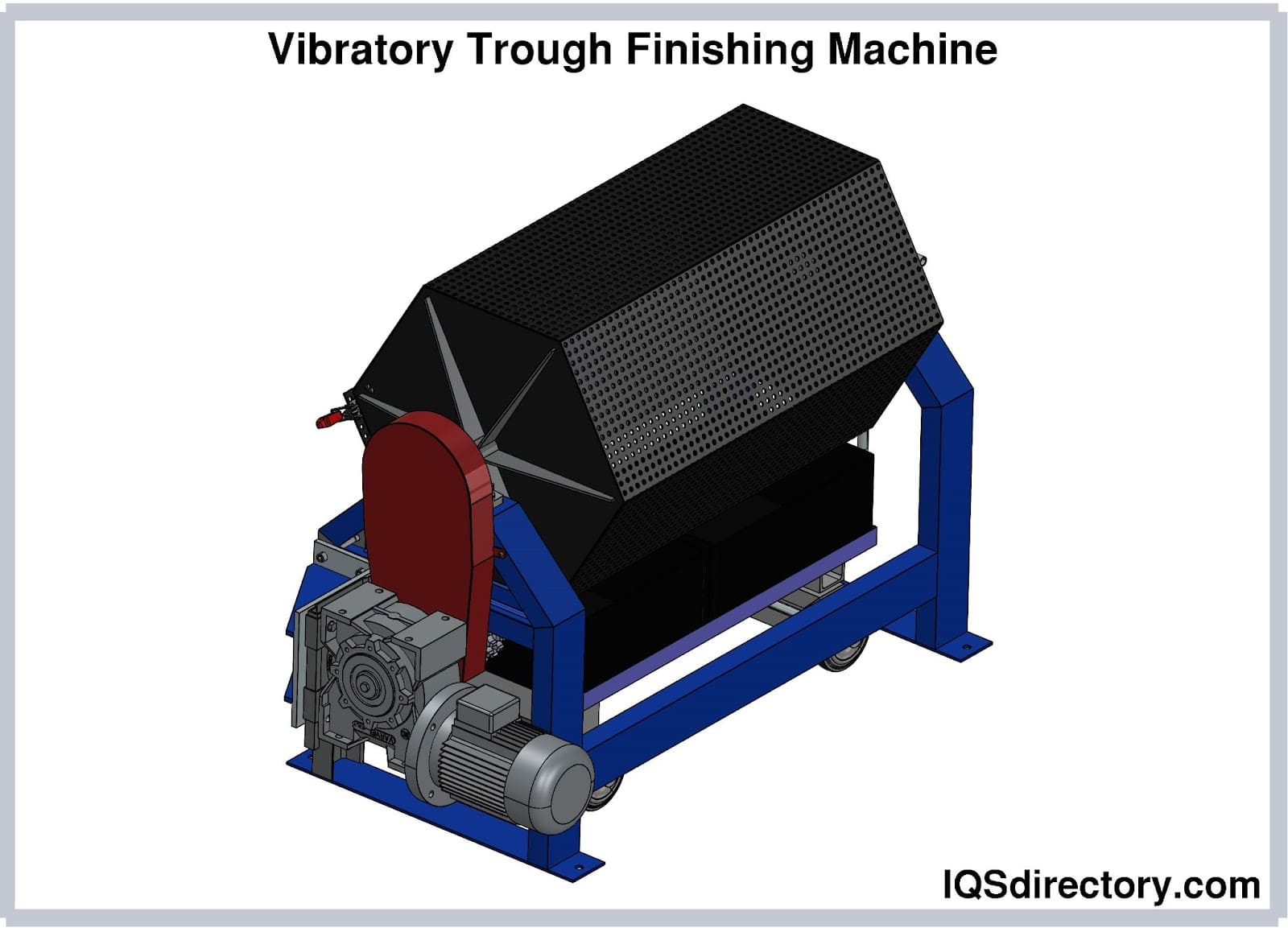

Vibratory Trough Finishing Machine

This type of machine is used in the finishing process for irregular, long, large, and delicate parts. It is mainly made up of a U-shaped tub and consists of divider plates and a lining of polyurethane.

These allow the creation of sections in the tub that separate the parts. An advantage of this is that it reduces the friction between the parts during the finishing process.

All of the operations of finishing can be performed here. They vary in size, capacities, widths, and lengths. Products can be made in very large quantities.

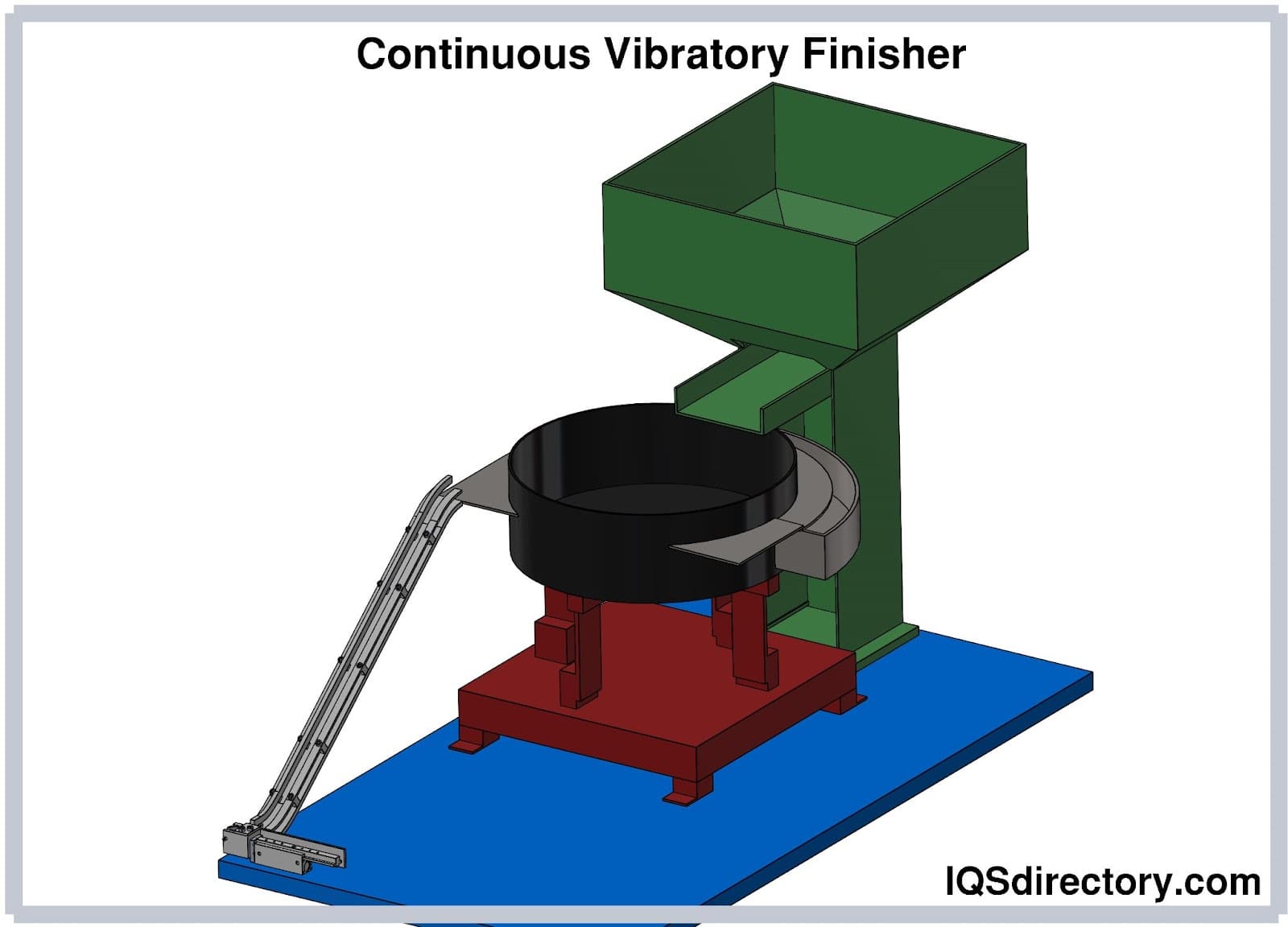

Continuous Vibratory Finisher

A continuous vibratory finisher performs by putting the parts at the end of the machine and afterward conveying them along with the media.

This is done while the process of finishing is still ongoing. At the other end, the finished parts are received. These finishers provide great productivity.

Vibratory Dual Finishing Machine

A vibratory dual finishing machine comprises both an outer chamber and an inner chamber. These are mostly used for performing dry and wet steps of vibratory finishing.

The inner chamber carries out steps that are heavy such as polishing, radiusing and deburring. To minimize friction and wear, this chamber also has a polyurethane lining.

The outer chamber carries out the cleaning and drying steps on the other side. There is a partition in between to ensure there is no mixing of contents in the chambers.

Vibratory Dryer

The vibratory dryer is capable of processing both large and small volumes of parts. Commercially, they are available in continuous and batch modes.

They have a uniquely designed tub that is full of heated drying media. Drying the parts usually takes place after the wet finishing process.

Applications and Uses of Vibratory Tumblers

There are many applications and uses of vibratory tumblers. They are used to descale, deburr, deflash, and polish workpieces.

They can also be used to strengthen the bonding of plating and coating materials by preparing the surface.

They also have an application in minimizing the sizes of irregularly shaped materials. Afterward, each workpiece will have its exact shape.

Advantages of Vibratory Tumblers

Vibratory tumblers produce very high volumes of parts. Compared to rotary tumblers, they are much faster at producing products. They are also available in different shapes, dimensions, and capacities. Vibratory tumblers can also finish different kinds of surfaces.

Vibratory tumblers are of great significance in the industry, and their great advantages over rotary tumblers have led them to gain their name and popularity. As new technologies emerge, new and better adjustments are being made to make them even more efficient.

Choosing the Proper Vibratory Tumbler Supplier

To make sure you have the most beneficial outcome when purchasing Vibratory Tumblers from a Vibratory Tumbler Supplier, it is important to compare at least 4 Companies using our Vibratory Tumbler directory. Each Vibratory Tumbler Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Vibratory Tumbler company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Vibratory Tumbler businesses with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services