Parts tumblers are tools that are used for the removal of burrs, scales, rust as well as other material that is unwanted on the surface of a part. Parts tumblers are an ideal solution when it comes to cleaning of equipment but they are not usually mentioned enough. Read More…

OTEC Precision Finish, Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Raytech Industries specializes in the manufacturing and sales of high-quality metal finishing equipment. Raytech offers vibratory tumblers, magnetic finishers, parts separators, finishing compounds, and finishing media. Raytech is an American-owned company and has been serving the needs of the industry since 1958 through our quality and innovative products.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

The Deburring Company is committed to providing superior service by using today's innovations to produce the highest quality product in a safe and efficient environment. The Deburring Company conforms to the ISO 9001-2000 requirements and implements continuous improvement efforts to ensure customer satisfaction.

More Parts Tumbler Manufacturers

What is a Parts Tumbler?

Many industries utilize parts tumblers for equipment cleaning; the primary industry being the automotive industry.

Vibratory parts tumblers and rotary parts tumblers are two of the most common applications of parts tumblers and the advantages of every type of part tumbler must be considered carefully when thinking of purchasing and adding one or more to a shop.

Types of Parts Tumblers

There are two main types of parts tumblers which are the vibratory parts tumbler and the rotary parts tumbler. These two main types also have different configurations.

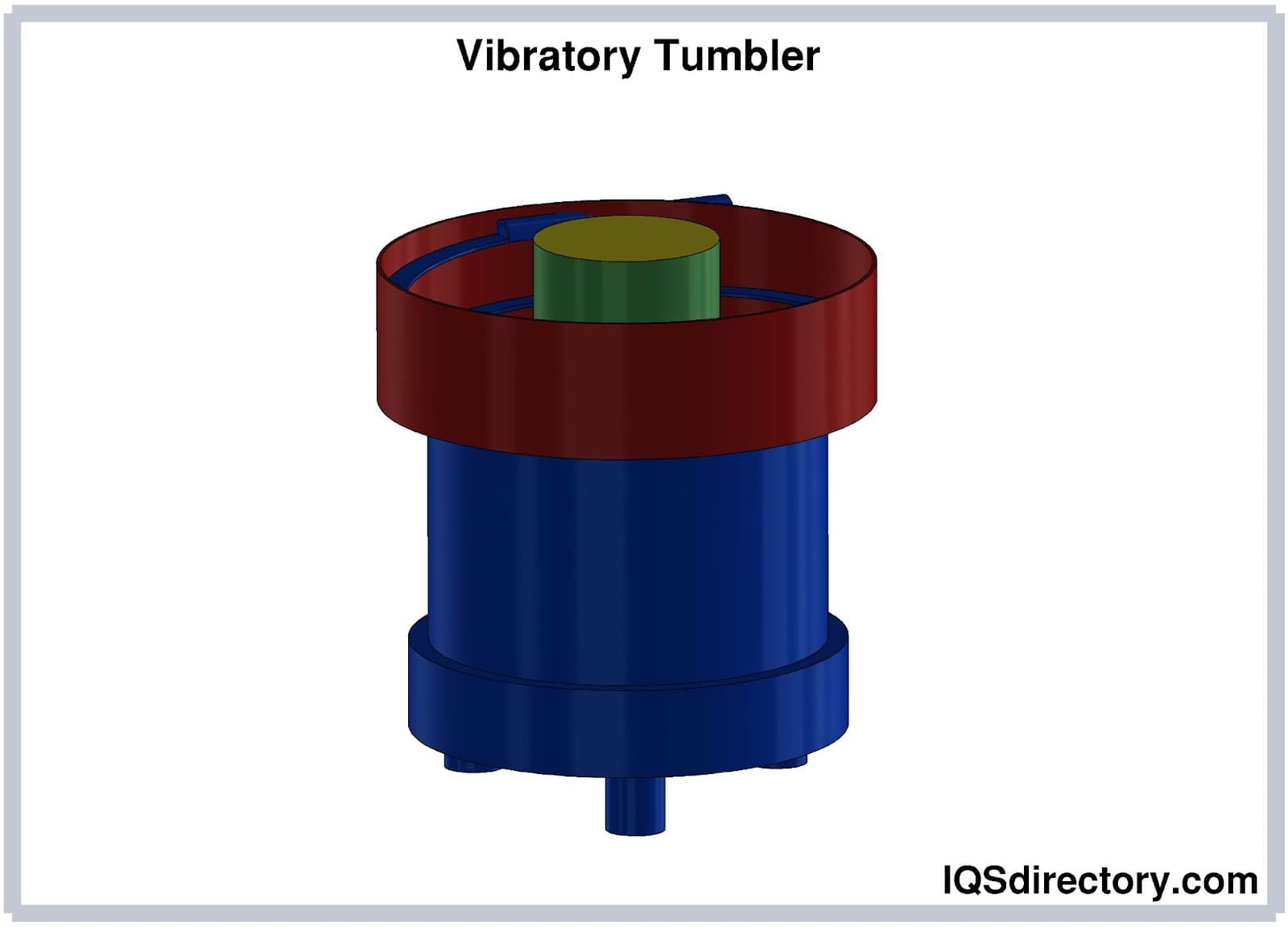

Vibratory Tumbler

A vibratory tumbler is defined as equipment that is used in the process of vibratory finishing. This vibratory finishing is one of the most used procedures when performing mass finishing. The very same parts are found in both vibratory parts tumblers and rotary parts tumblers.

Vibratory parts tumblers work by agitation in a side-to-side movement at high speeds. This will cause the occurrence of friction and therefore continuous grinding amongst the parts enclosed.

The vibratory tumblers put together the workpieces and parts in a tub which is full of specially shaped pellets. Thereafter, the contents inside the tub are exposed to a vibration force that is applied.

The motor in the vibratory tumbler is used to apply the vibrational force. The finishing process is aided by a chemical which is then maintained inside the tub.

The vibration makes the workpieces grind and rub against each other as well as against the media. This yields the end product of neatly polished workpieces.

Generally, the barrel tumbler grinds at an applied force whereas the vibratory tumbler moves faster than free fall. The difference between the vibratory tumbler free fall force and that barrel tumbler is about 5 to 10 times.

Rotary Tumblers

Rotary parts tumblers have components that are called a cylindrical and hexagonal barrel, a motor, a base, a gear assembly, and a dive. In order, for the creation of deburring action, rotary tumblers make use of rotational motion.

They achieve this with the aid of abrasive tumbling media for the enabling of the occurrence of a sliding action. Many different types of tumbling media are available and some examples of these are: ceramic, organic media like walnut shells and corn cob, small abrasive steel, and plastic.

Both rotary and vibratory parts tumblers can be utilized in both dry and wet deburring.

Applications of Parts Tumblers

The applications and uses of parts tumblers include:

- Descaling

- De-rusting

- Deburring

- De-flashing

- Polishing

- Strengthening of the bonding of plating and coating materials

Benefits of Parts Tumblers

The benefits of parts tumblers include:

- Rotary tumblers are very quiet in their operation.

- Rotary parts tumblers are suitable for the gentle deburring of pieces, polishing as well as cleaning at an operational cost that is low.

- Vibratory parts tumblers offer an advantage of increased load capacity.

- Vibratory parts tumbler also have an advantage of a finishing time that is decreased as well as a smoother polish.

- Vibratory tumblers are suitable for the manufacture of parts in high volumes.

- Vibratory parts tumbles are faster in parts production.

- They are capable of finishing the surface of plastic safely as well as ceramic and metal workpieces in the event that the appropriate vibratory action, media and the type of vibratory finishing are utilized.

- There are so many different shapes, capacities and dimensions of vibratory tumblers.

- They are capable of being automated highly for the provision of better control over the finishing process.

Thus, parts tumblers are a great solution for the cleaning of equipment. They include two main types which are rotary and vibratory parts tumbler. Both rotary and vibratory parts tumblers can be utilized in dry and wet deburring. These two main types offer different benefits in their operation. Therefore careful consideration must be made when selecting a parts tumbler for a specific operation.

Choosing the Proper Parts Tumbler Company

To make sure you have the most positive outcome when purchasing Parts Tumbler from a Parts Tumbler Supplier, it is important to compare at least 4 Manufacturers using our Parts Tumbler directory. Each Parts Tumbler Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Parts Tumbler company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Parts Tumbler companies with the same message.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services