A tumbling barrel is defined as a drum where objects are packed in a loose manner and then brought to an action of tumbling for polishing or mixing. Read More…

OTEC Precision Finish, Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Raytech Industries specializes in the manufacturing and sales of high-quality metal finishing equipment. Raytech offers vibratory tumblers, magnetic finishers, parts separators, finishing compounds, and finishing media. Raytech is an American-owned company and has been serving the needs of the industry since 1958 through our quality and innovative products.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

The Deburring Company is committed to providing superior service by using today's innovations to produce the highest quality product in a safe and efficient environment. The Deburring Company conforms to the ISO 9001-2000 requirements and implements continuous improvement efforts to ensure customer satisfaction.

More Tumbling Barrel Manufacturers

What Is a Tumbling Barrel?

It can also be taken as a cask that continuously revolves and at the same time allows the objects to undergo a polishing or drying process by being continuously wired about.

How Tumbling Barrels Function

The tumbling barrels work by making use of tumbling parts that are inside in a rotating barrel. Therefore there is creation of frictional force by the tumbling parts. This friction is on the tumbling parts on other materials such as compounds and media as well as on itself.

The production of best surface finishes using this method of finishing by barrels relies on proper selection and correct use of abrasives, lubricating agents, tumblers, polishing agents, and carrying agents.

The barrel tumbling process is also called barrel finishing. Compounds and media are put in a eight or six sided barrel at a predetermined velocity and rotated in order to deburr, round corners, descale, deflash, grind, burnish, radius, and improve surface finish.

Types of Tumbling Processes

The types of tumbling processes include:

Wet Tumbling

In wet tumbling, the barrels mostly used are oblique and horizontal barrels. Horizontal barrels are usually hexagonal or octagonal in design or shape. This type of tumbling is preferred since it has a good action on tumbling and a large capacity.

The barrels are made of steel and have linings of rubber, neoprene, vinyl, urethane, or neoprene. The barrel life is prolonged by the minimized impact on the barrel caused by the lining.

When filling of the barrel is done to its half with media and parts, there is addition of water to a few inches below the load. More water means a better finish. The tumbling process can be six to 24 hours.

In order to increase the load weight to light plastic parts there is need for addition of hardwood media or smooth ceramic in a dry process. The barrel and the parts have to be rinsed with fresh water afterwards. There is then removal of parts by such methods as spinning dry or tumbling with corn cob grit.

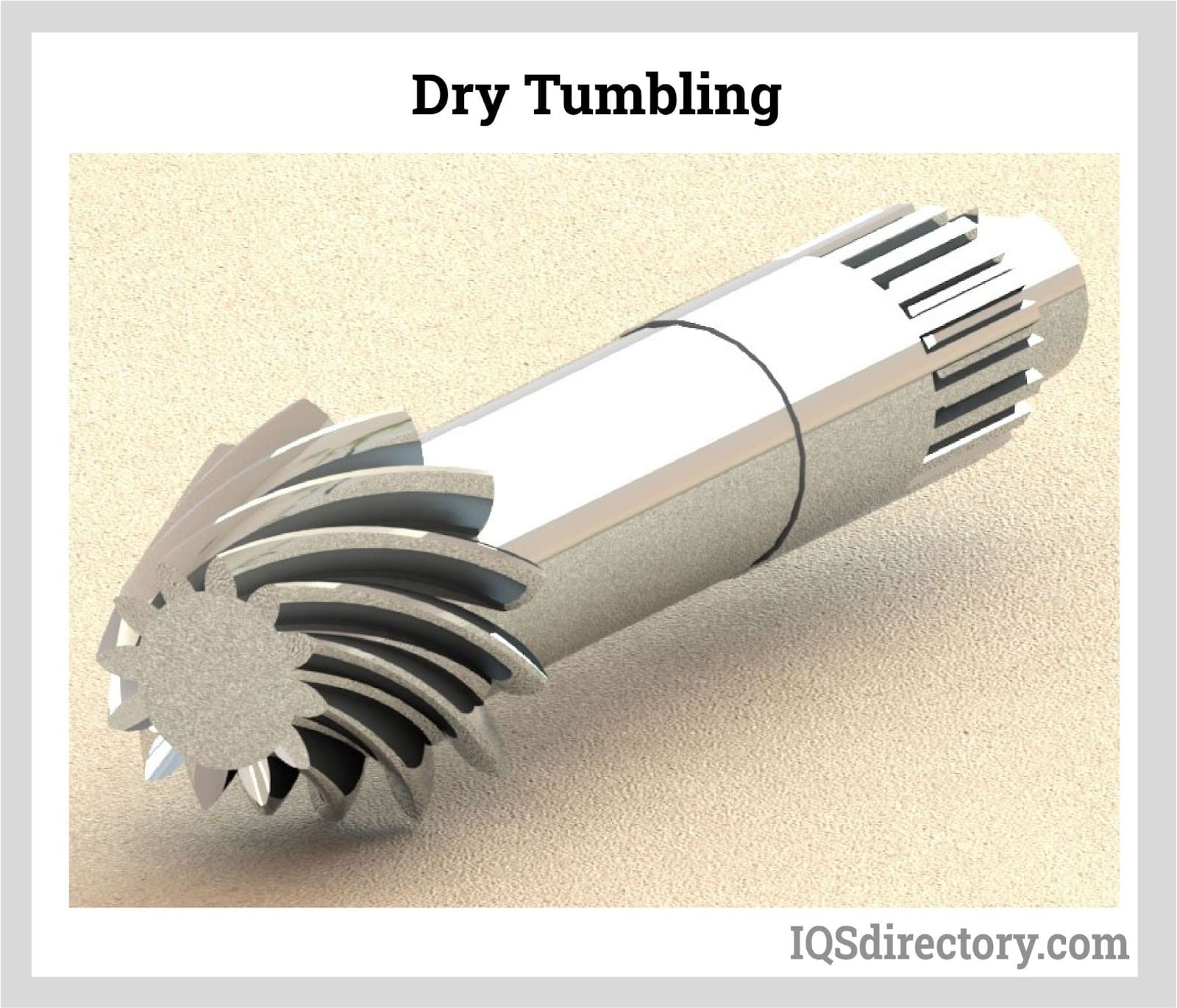

Dry Tumbling

In this process the barrel used mostly is the horizontal octagonal barrel. It consists of a skin of metal and lining of hardwood which is replaceable.

There are dry barrels which are double decked and this puts one barrel on top of the other. These barrels will be set in the same frame. One advantage of this is that it saves floor space.

There is production of high and quality finishes by making use of walnut shells or wood pegs. These have to be treated by an abrasive and wax. Materials such as plastics need soft media like wood pegs in order to minimize damage.

Applications and Uses of Tumbling Barrels

Tumbling barrels have numerous applications and uses in the commercial sector as well as the industrial sector. Their application is in the retail shops. They are used for jewelry polishing as well as other metal applications.

They are also used in the manufacturing industry for processes of fabricating plastics as well as metalwork. They also have a great deal of use and application in the construction industry for the deburring of materials of a building like concrete.

Advantages of Tumbling Barrels

Tumbling barrels have the following benefits or advantages:

- They minimize cost as compared to using hands.

- They are capable of producing many products, very little handling is needed and the parts produced are stronger and tougher.

- Stress relief is guaranteed as well as the blending, castings, and forgings. High and bright finishes are produced.

- Another advantage of these is that tumbling time is saved if there is a right way of machining the parts.

Thus, a tumbling barrel is defined as a drum where objects are packed in a loose manner. After they are brought to an action of tumbling as for polishing or mixing. They have been of great impact to humanity in the various sectors of industry in which they apply. These barrels as new technology appear to continue to advance and therefore make the end finishes much better.

Choosing the Proper Tumbling Barrels Supplier

To make sure you have the most productive outcome when purchasing Tumbling Barrels from a Tumbling Barrels Supplier, it is important to compare at least 4 or 5 Suppliers using our list of Tumbling Barrels manufacturers. Each Tumbling Barrels Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Tumbling Barrels company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Tumbling Barrels businesses with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services