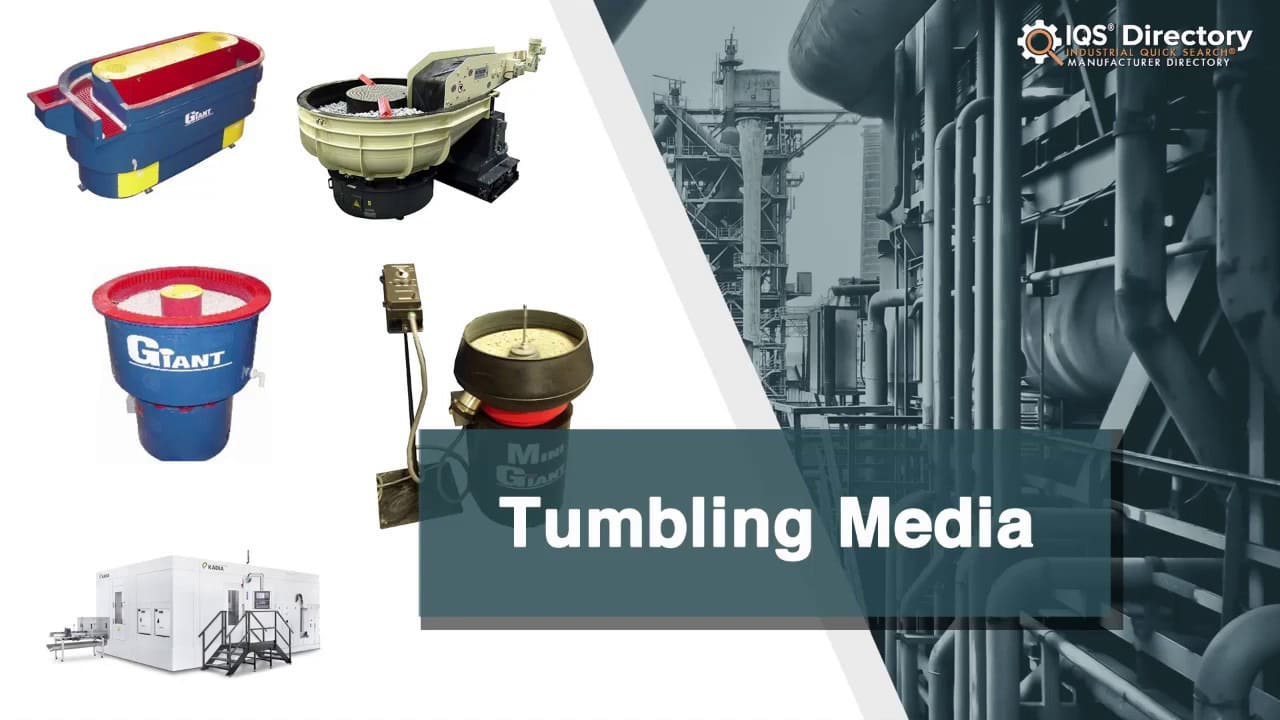

Tumbling media refers to preformed, abrasive material that is used for polishing and finishing parts made up of various materials. By scrubbing parts against abrasive materials, those surfaces are thoroughly abraded and smoothed. The process also helps in removing rough metal ridges called burrs. Read More…

OTEC Precision Finish, Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Raytech Industries specializes in the manufacturing and sales of high-quality metal finishing equipment. Raytech offers vibratory tumblers, magnetic finishers, parts separators, finishing compounds, and finishing media. Raytech is an American-owned company and has been serving the needs of the industry since 1958 through our quality and innovative products.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

The Deburring Company is committed to providing superior service by using today's innovations to produce the highest quality product in a safe and efficient environment. The Deburring Company conforms to the ISO 9001-2000 requirements and implements continuous improvement efforts to ensure customer satisfaction.

More Tumbling Media Manufacturers

What is Tumbling Media?

Tumbling media refers to a combination of abrasives and binders. These use a tumbling technique which results in the smoothing and polishing of a rough surface on small parts.

Types of Tumbling Media

The types of tumbling media include:

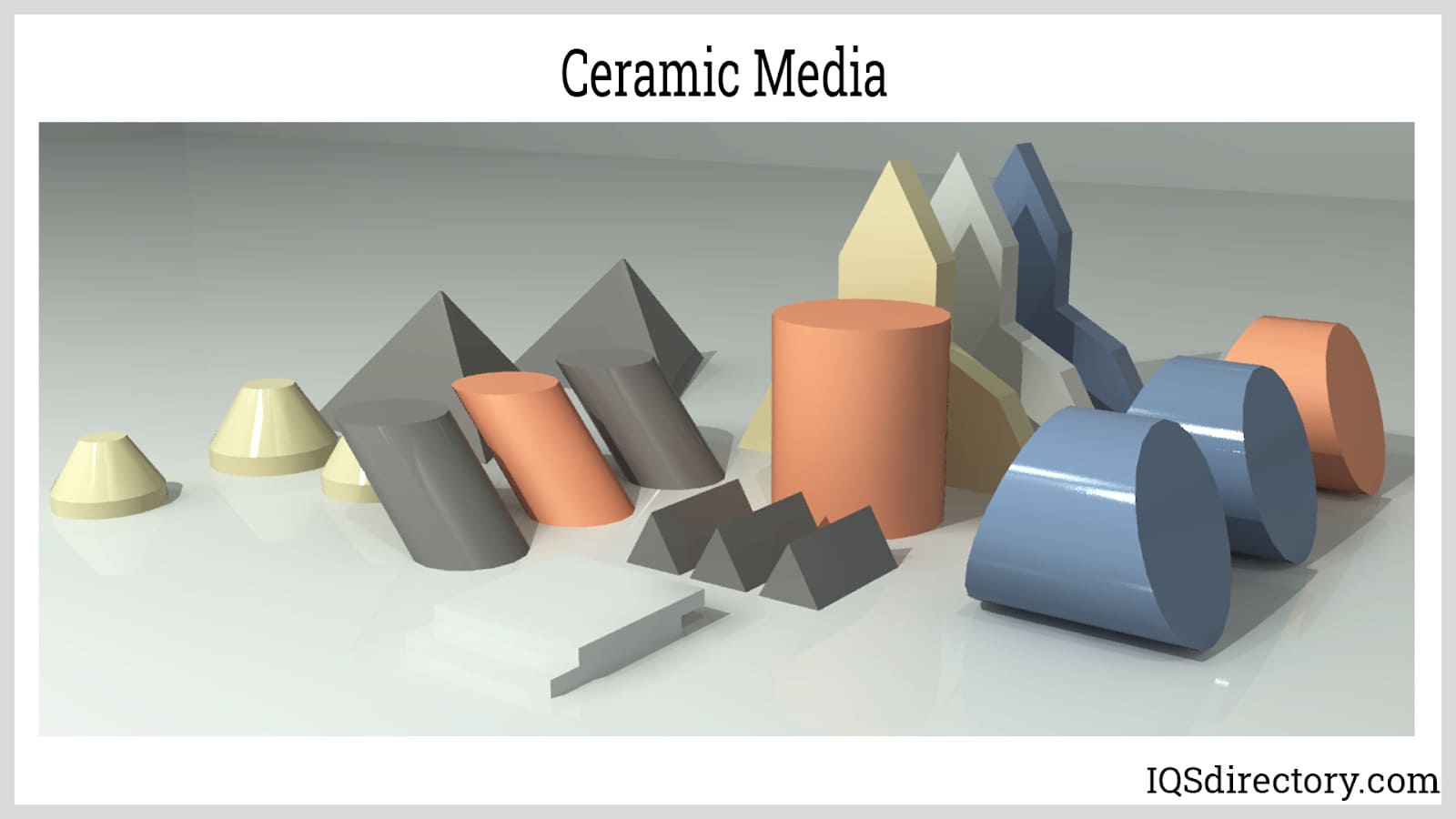

Ceramic Media

This is the most common finishing media. Ceramic media have high density, high durability and toughness, and because of this they are ideal for deburring, edge radiusing, and polishing hard metals such as steel and titanium.

For metal parts, ceramic media can be used for removing rust. They are preferred in areas where heavy or fast grinding is performed.

Due to excessive forces and wear, ceramic media can chip, and resulting loose ceramic particles can be later embedded in the small holes of a part.

Steel Media

Steel media is made up from hardened carbon and high-density stainless steel. Their properties include high strength and durability, and this enables their prolonged service life and helps in improving their resistance to wear.

Steel media are used in heavy duty burnishing and polishing due to the fact that they can apply large amounts of pressure during the vibration process. They can be used on brass, steel, aluminum and plastic parts.

Using steel media in the finishing process results in a bright, burr-free and smooth surface.

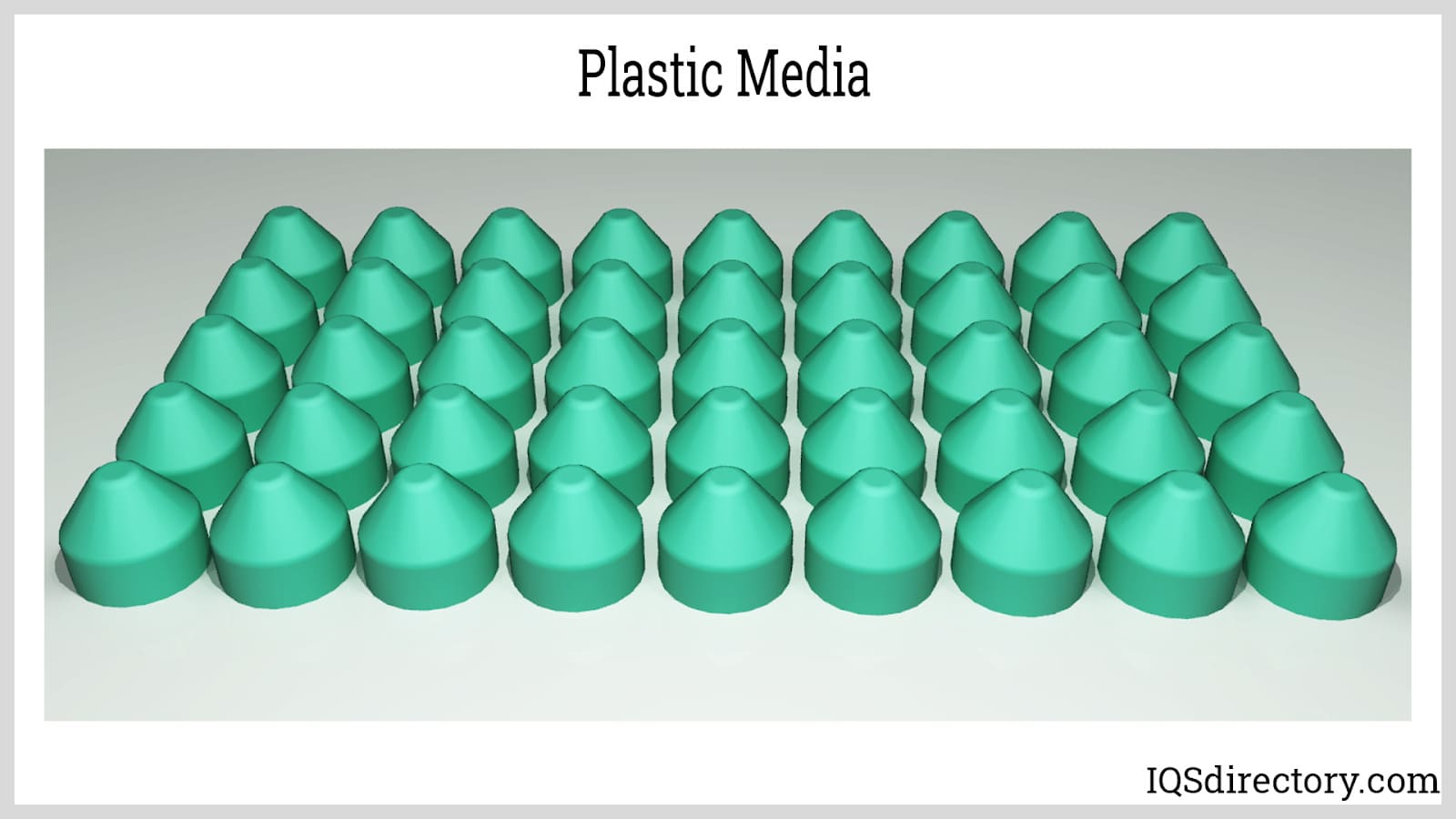

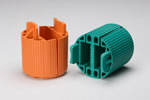

Plastic Media

Plastic media is essential for polishing, deburring, burnishing, and cleaning softer metals. Such softer metals include brass, zinc, and aluminum.

This type of media is generally less dense compared to ceramic and steel media. Thus, they can more safely perform vibratory finishing on fragile and threaded parts.

Plastic media is used in mild cutting and in abrasive finishing. They produce workpieces which are soft, with bright surfaces and edges after the finishing process.

Polymers based on polyester, urea and formaldehyde are commonly used to make plastic media. To finish workpieces with more specific results, there are various formulations of plastic media, including:

Low Density Plastic Media

These are used in the finishing process of softer materials since they will not cause impingement and distortion. They are also used for flash removal, deburring, burnishing, and the process of pre-coating surface preparation.

High Density Plastic Media

These are made to finish ferrous and non-ferrous metals and hard parts. Some applications include deburring hard metals, finishing fine and intricate parts, and fast cutting processes.

High Performance Density Plastic Media

High performance density plastic media are mainly used for finishing parts that are made up of ferrous metals.

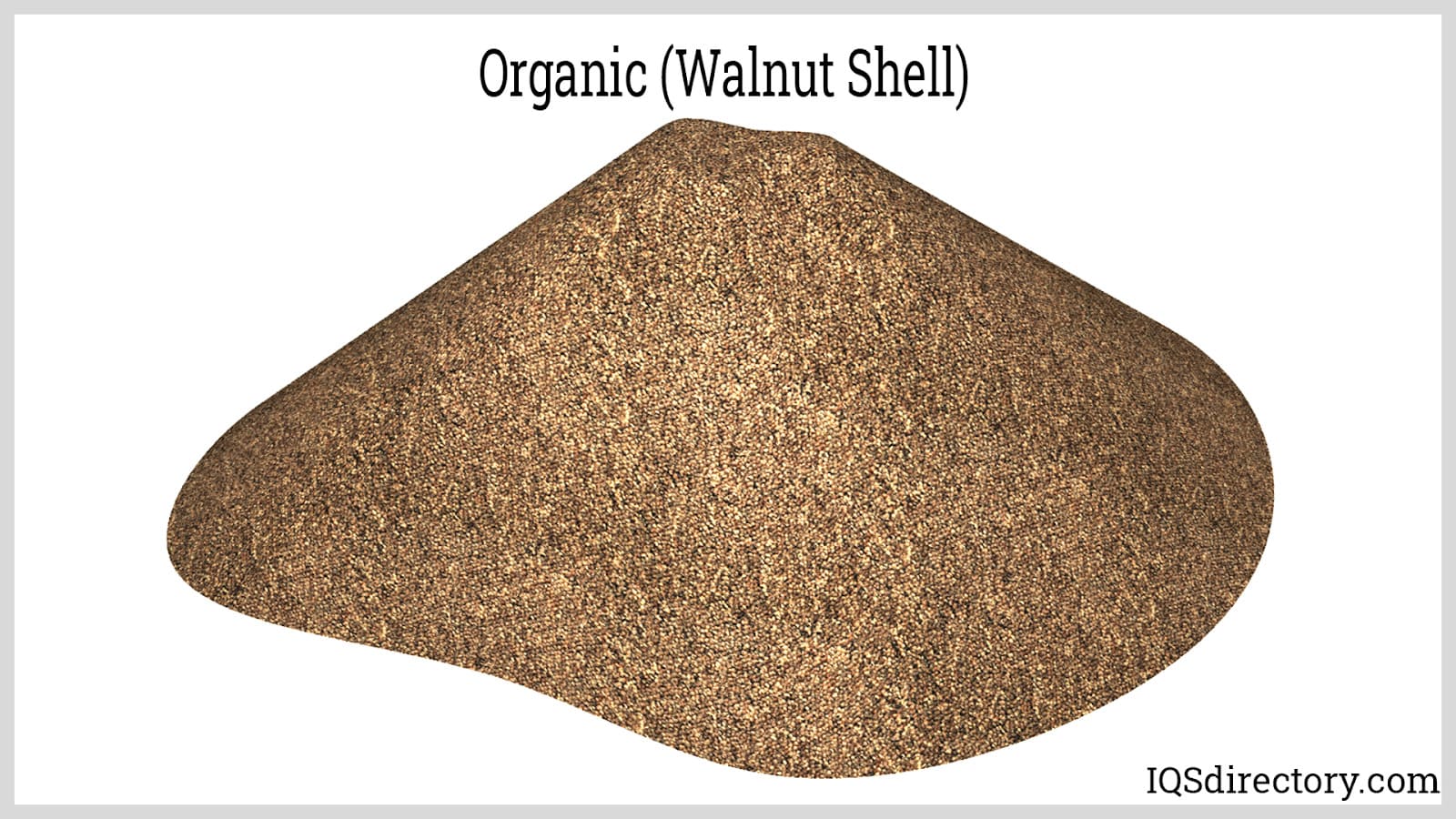

Organic Media

These are lightweight media that are typically made up of walnut shells and crushed corn cobs. Because of their properties, they are environmentally friendly, durable and biodegradable.

They are preferred for light and medium deburring and used in the process of drying parts after vibratory finishing. After the finishing process, they result in the production of glossy surfaces on metal parts when used with polishing paste.

Organic media are used to properly finish pieces of jewelry. By using crushed corn cobs as organic finishing media, they will absorb oils and moisture from the surface of the workpiece. This advantage leads to an enhanced resistance to corrosion.

Applications of Tumbling Media

Tumbling media are used in firearm cartridge polishing.Polishing clean brass cartridge casings with a vibratory bowl finisher results in saving ammunition costs.

Their applications also include the use of jewelry polishing, as mass jewelry polishing systems and jewelry burnishing has become an effective time- and money-saving tool compared to traditional methods.

Finally, tumbling media can effectively remove calcium and mineral deposits left by water.

Choosing the Correct Tumbling Media Supplier

To make sure you have the most constructive outcome when purchasing Tumbling Media from a Tumbling Media Supplier, it is important to compare at least 6 Manufacturers using our list of Tumbling Media manufacturers. Each Tumbling Media Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Tumbling Media business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Tumbling Media businesses with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services