The processes of brushing, buffing, polishing, and finishing any metal material are carried out by polishing machines, also known as buffing machines. Polishing machines are versatile because they allow the work of elements of all shapes and sizes with various types of finishes, from cleaning to mirror finishing accomplished with abrasive pastes. While polishing machines can assist items in being finished and perfected in various ways, their primary function during deburring is to remove burrs, ragged edges, and other extra material while leaving the rest of the material alone. Read More…

OTEC Precision Finish, Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Raytech Industries specializes in the manufacturing and sales of high-quality metal finishing equipment. Raytech offers vibratory tumblers, magnetic finishers, parts separators, finishing compounds, and finishing media. Raytech is an American-owned company and has been serving the needs of the industry since 1958 through our quality and innovative products.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

The Deburring Company is committed to providing superior service by using today's innovations to produce the highest quality product in a safe and efficient environment. The Deburring Company conforms to the ISO 9001-2000 requirements and implements continuous improvement efforts to ensure customer satisfaction.

More Polishing Machine Manufacturers

Applications of Polishing Machines

Deburring is a subsequent step for items that have recently undergone process machining and are largely served by polishing equipment. Burrs can be left behind during the engraving, drilling, turning, welding, extruding, and etching processes of machining. It helps prevent accidents, makes something smoother or shinier than before, and makes machined parts ready to be assembled as finished product parts. These are only a few reasons superfluous and sharp material is removed from an object.

Many businesses, including industrial production, construction, the automobile and aviation industries, and retail, use polishing machines because it is a common necessity. Hinges and bolts are examples of small components polished in industrial manufacture since they only require little material removal.

They polish and deburr building materials like marble, stone, tile, and concrete in construction. Hubcaps and metal body frames are exterior parts of land and air vehicles that gleam thanks to polishing machinery. Finally, polishing machines are used in various retail settings, including polishing jewelry's accent stones, fine metals, and precious stones.

Vibration or Rotation Polishing

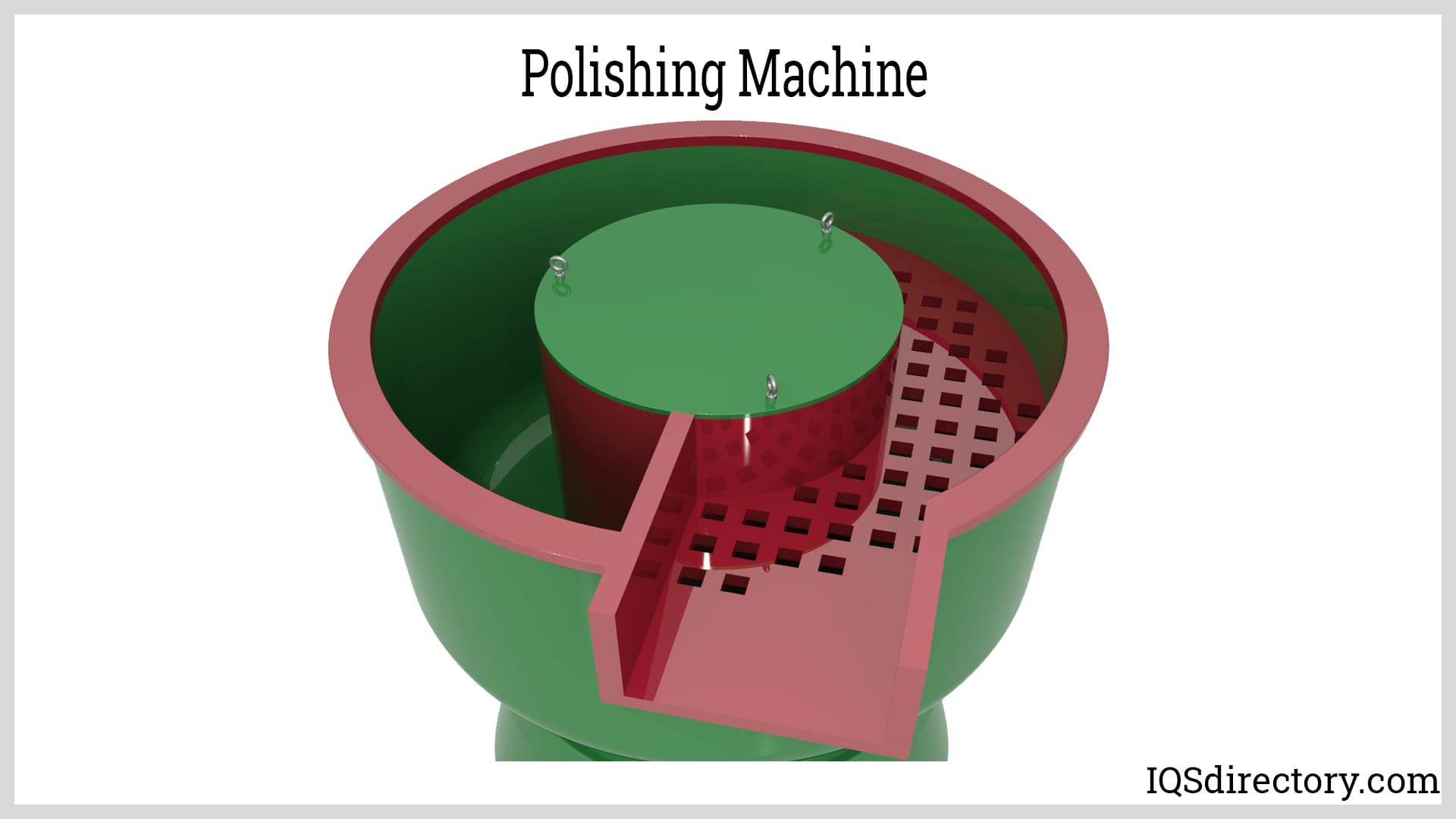

Equipment that can be categorized as polishing machines is fairly varied. While polishing machines employ various tools, they all work by applying vibration or rotational force. Typically, a vibratory tumbling barrel, also known as a vibratory tumbler, is used to achieve vibration deburring and polishing. Vibratory tumblers use prolonged vibration durations and, frequently, abrasive media to remove burrs from items placed inside a barrel.

In addition, smaller pieces and loads are often polished in vibratory tumblers. Other small components and materials tools include polishing lathes, handheld wheels, belt grinders, and abrasive nylon brushes. With a tumbler barrel that revolves around an axis for a predetermined time and may or may not includes a form of media, rotational polishing is accomplished.

Abrasive Media

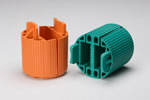

Sharp and rough edges can be efficiently smoothed when an abrasive material is present and a sliding motion is produced by rotation. Very fine abrasive deburring compounds, like sand, ceramics, fine-grit aluminum polycarbonates, and oxides, are examples of the media types used by polishing machines. Polishing machines frequently require extra components, such as belts, wheels, or brushes, if they intend to polish big portions.

Furthermore, robotic polishing and other automated techniques are frequently needed for large-part polishing. One such instance is buffing during polishing; this process uses very little abrasion to create exceedingly smooth and lustrous surfaces. In addition, buffing chemicals, which can generate a range of hues, can be brought in during the polishing process to coat surfaces with protective coats.

Types of Polishing Machines

Different combinations of cotton, cloth, rubber, and mineral abrasives can create polishing wheels, belts, and grinders, depending on the polished material and the desired quality. Instead of removing extra material from a product's surface as deburring machines do, polishing's purpose is to make the surface smooth. Because of this, polishing materials tend to soften the item's surface and have minimal abrasive qualities.

Extremely low abrasion media are also used in buffing. Buffing can be done by hand and with the help of an automated machine. To generate incredibly smooth and bright surfaces, buffing compounds are occasionally applied during polishing. Polishing frequently occurs in stages, beginning with a tumbling medium with a bigger particle size and advancing toward a smaller, finer abrasive substance that produces a smoother finish.

Manufacturing of screws and fasteners, forging, metal stamping, and machined parts for both function and aesthetics, household tile, marble, and concrete manufacturers, auto manufacturers (to polish and buff car parts), and the food and dairy industries (to achieve sanitary conditions in metal storage containers) are among the industries that require polishing equipment.

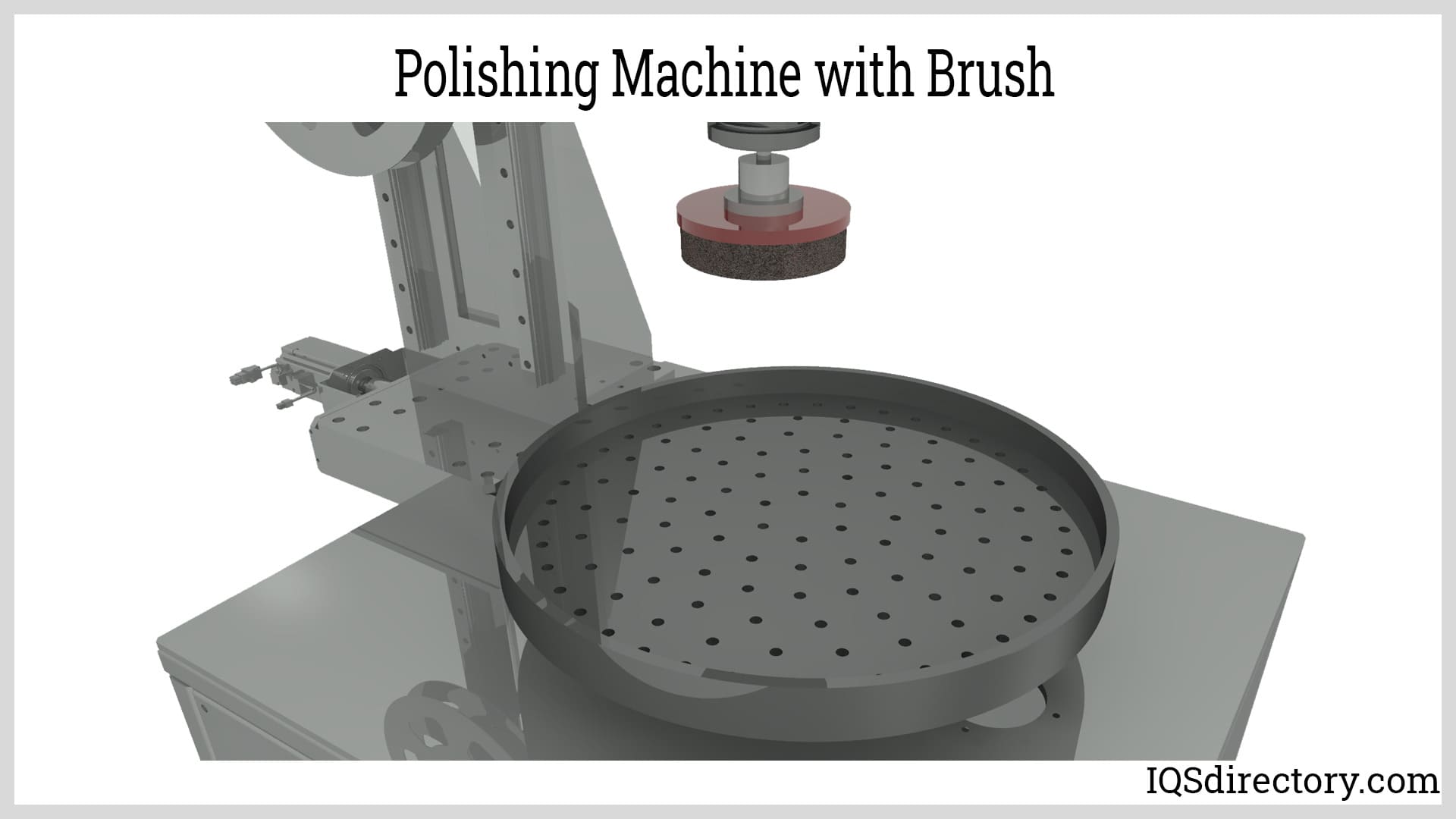

Polishing Brushes

Polishing brushes are multipurpose polishing tools that can take many different forms. As cylinder or roller brushes, they might be automated and coupled to a revolving motor. These polishing devices smooth off the surface of anything they encounter. Polishing brushes can be made in disc and cup shapes and mounted to any handheld power tool, such as a hand drill, to serve smaller applications. These brushes may be found in various sizes, making it easy and practical for anyone to swiftly, expertly, and affordably polish items.

Other polishing brushes are created specifically to operate with commercial equipment as part of an automated cleaning procedure. When brushes like these wear out, a replacement is simple to make. For example, large, rounded polishing brushes can be used on automobiles to remove waxing streaks and replace them with a shining, smooth surface. Even chrome products and components can be polished using them. Polishing brushes are ideal for delicate items or products that cannot be polished safely with a tumbler or power tool.

Choosing the Correct Polishing Machine Manufacturer

To make sure you have the most productive outcome when purchasing Polishing Machines from a Polishing Machine Supplier, it is important to compare at least 4 or 5 Manufacturers using our list of Polishing Machine companies. Each Polishing Machine Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Polishing Machine business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Polishing Machine businesses with the same quote.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services