A tumbler is a barrel or drum on finishing and deburring equipment that holds items during the finishing process. Rotary and vibratory tumblers are the two primary types of tumblers used in component finishing and polishing operations. Tumblers come in a wide range of sizes. For example, hobbyists’ tumblers for stone polishing will be smaller than those for cleaning industrial parts.Read More…

OTEC Precision Finish, Inc. is a world-class supplier of mass finishing equipment and supplies. Our primary products include centrifugal disc, drag and stream finishing machines to meet all of your deburring, polishing, grinding and honing requirements.

Raytech Industries specializes in the manufacturing and sales of high-quality metal finishing equipment. Raytech offers vibratory tumblers, magnetic finishers, parts separators, finishing compounds, and finishing media. Raytech is an American-owned company and has been serving the needs of the industry since 1958 through our quality and innovative products.

Great Lakes Finishing Equipment, Inc. is a leading supplier of the deburring equipment, machines, and supplies for all your mass finishing projects. This equipment includes continuous systems, vibratory bowls, tubs, and high energy centrifugal barrel machines. Let our deburring specialists work with you to find the best deburring machinery for your project.

The Deburring Company is committed to providing superior service by using today's innovations to produce the highest quality product in a safe and efficient environment. The Deburring Company conforms to the ISO 9001-2000 requirements and implements continuous improvement efforts to ensure customer satisfaction.

More Tumbler Manufacturers

Types of Tumblers

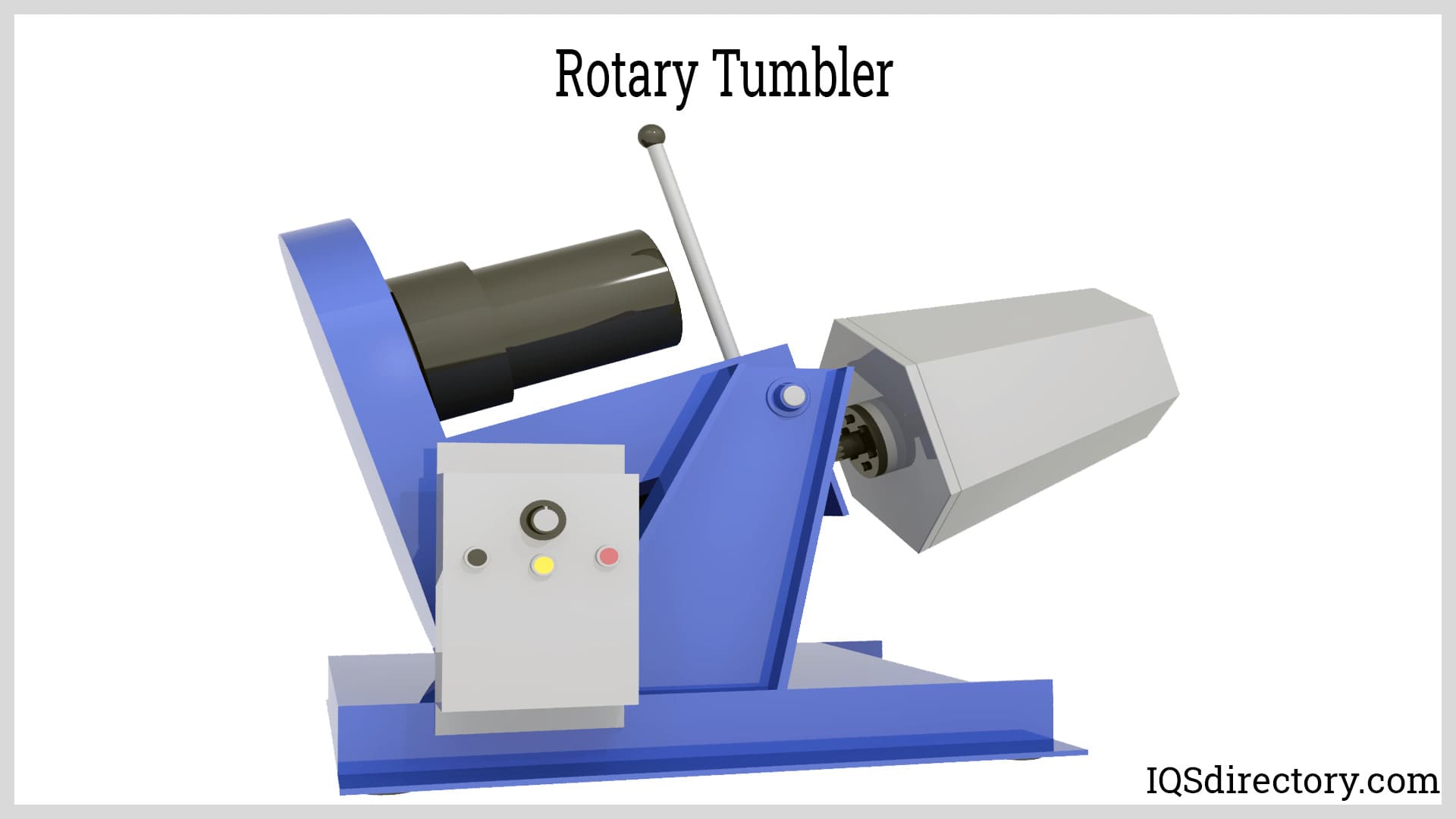

Rotary Tumblers

Most people picture a tumbler as a barrel or drum turned horizontally on its side. Two parallel rotating shafts support the rotation or revolving of a rotary tumbler. Rotary tumblers have capacities ranging from a few pounds to huge, robust ones that may handle several hundred pounds. Rotary tumblers are simpler to load than other tumbler kinds. Rotary tumblers include a rubber lining that reduces noise.

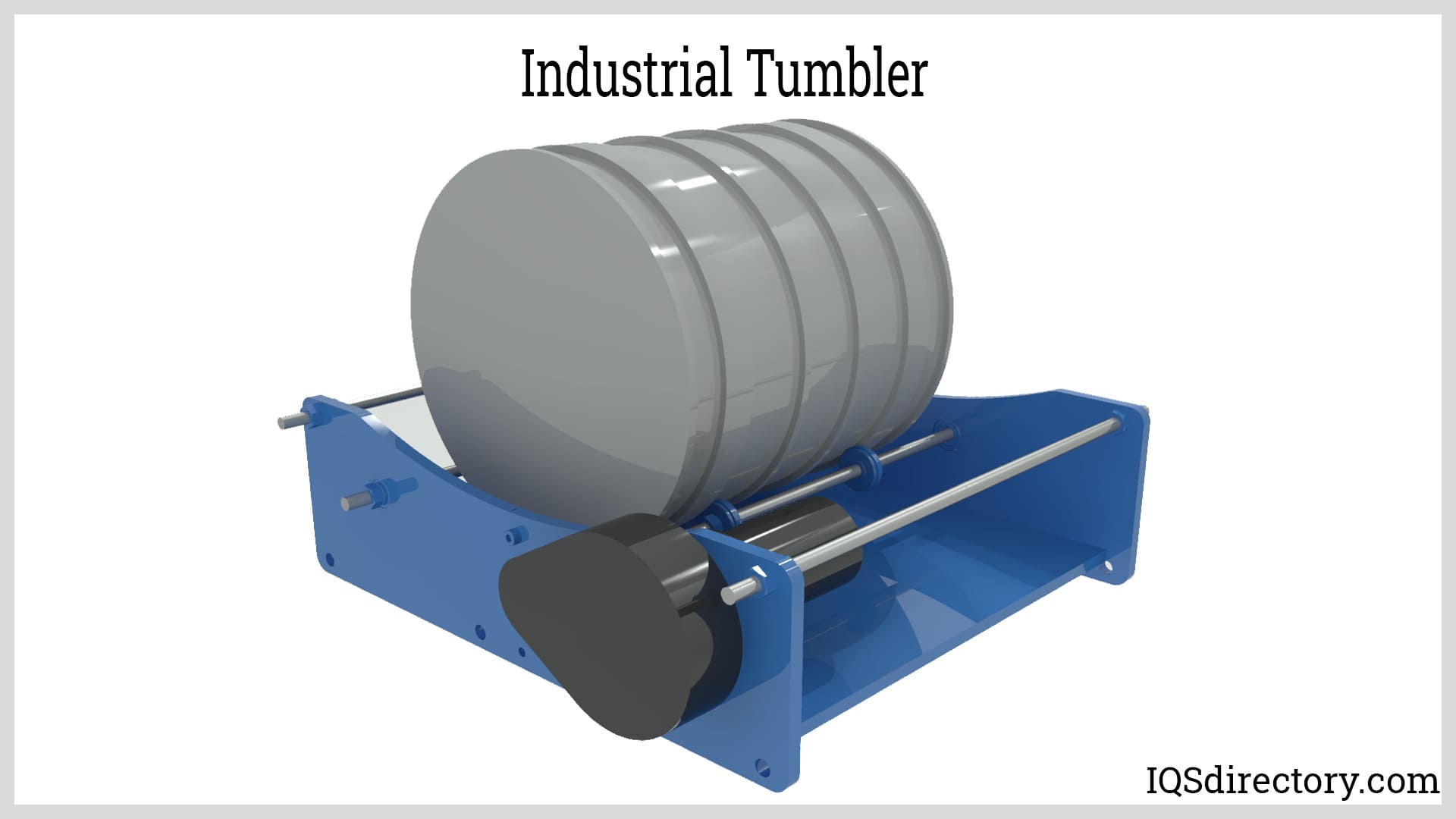

Vibratory Tumbler

A vibratory tumbler is the second most common tumbler. The barrel in a vibratory tumbler stays still while it is being tumbled. There are typically two types of vibratory tumblers. A mechanical vibratory tumbler uses a motor to sustain vibrations. An electrical vibratory tumbler uses magnetic energy. The objects in a vibratory tumbler maintain their shape.

For instance, a cube placed in a vibratory tumbler will still emerge a cube, whereas a cube placed in a rotary tumbler will have all its edges worn smooth. In general, vibratory tumblers produce faster results than rotary tumblers. Regardless of the tumbler type chosen, the components will shake, rock, and roll to the proper degree of smoothness.

Tumbler Design & Function

The components and tumbling material mix in rotary tumblers. Hexagonal or cylindrical tubs spin horizontally. This cleans, polishes, and deburrs the components. The size of the barrel, the materials' hardness, and the level of finishing required will affect how quickly the parts rotate. The abrasive media in the vibratory tumblers come into contact and rub against one another. The vibration produces a cyclonic downward motion, and the ensuing friction leads to deburring and polishing.

When purchasing a tumbler, manufacturers should consider the barrel capacity, load limits, volume restrictions, engine size, and the consequent motion or vibration. The motor powering the tumbler must endure continuous duty. To prevent overheating, some tumblers include cooling options for motors. A lubricant, such as water, can be introduced to the tumbling process to promote polishing.

Tumblers with lubricant have a drainage feature to remove the liquid and grit. Industrial part manufacturers and machinists use tumblers for bulk finishing and cleaning, even though small rotary and vibratory tumblers are increasingly becoming hobbyists' equipment.

Abrasive media

In the finishing process, tumblers use tumbling or deburring media to generate friction with unfinished metal or plastic parts, jewelry, rough stones, etc. With varying degrees of hardness and abrasion, common abrasive media types include steel, plastic pellets, ceramic particles, walnut shells, and corn cob media.

The friction produced by the motion of tumbling when the abrasive medium is placed within the barrel aids in burnishing, polishing, and cleaning the surfaces of the parts. Industrial producers employ vibratory tumblers with more abrasive media for mass finishing and deburring, whereas rotary tumblers with wet media are used for mass part cleaning, polishing, and cement mixing.

Choosing the Right Tumblers Supplier

To make sure you have the most positive outcome when purchasing Tumblers from a Tumblers Manufacturer, it is important to compare at least 6 Suppliers using our list of Tumblers manufacturers. Each Tumblers Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Tumblers company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Tumblers businesses with the same form.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services