New England Metal Finishing, Inc.

New England Metal Finishing, Inc.Request A Quote

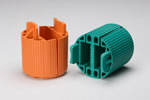

Windsor, CTNew England Metal Finishing, Inc. is a leading provider of comprehensive metal finishing solutions, specializing in deburring machinery and services. With decades of experience in the industry, the company has established itself as a trusted partner for businesses seeking high-quality deburring solutions in New England and beyond. Deburring Machinery Products: New England Metal Finishing offers a wide range of advanced deburring machinery products designed to meet the diverse needs of its customers. These products are specifically engineered to remove burrs, sharp edges, and imperfections from metal components, ensuring optimal functionality, safety, and aesthetics. The company's deburring machinery product lineup includes: Rotary Deburring Machines: New England Metal Finishing provides robust and versatile rotary deburring machines that utilize rotating brushes, belts, or abrasive discs to effectively remove burrs and smooth surfaces. These machines can handle a variety of part sizes and geometries, offering flexibility and precision in the deburring process. Abrasive Flow Machining (AFM) Systems: AFM systems offered by New England Metal Finishing employ a unique process of extruding a specially formulated abrasive media through the internal passages of the workpiece. This controlled flow of abrasive media effectively removes burrs, while also improving surface finish and edge quality. AFM is particularly suitable for complex internal geometries, intricate shapes, and delicate parts. Ultrasonic Deburring Equipment: New England Metal Finishing's ultrasonic deburring equipment utilizes high-frequency vibrations and cavitation to remove burrs and contaminants from metal surfaces. This non-abrasive method is gentle yet highly effective, making it suitable for delicate and precision parts where surface integrity is critical. Service Capabilities: In addition to their cutting-edge deburring machinery products, New England Metal Finishing offers a comprehensive range of service capabilities to meet the unique needs of their customers. These capabilities include: Customized Solutions: The company understands that each customer's deburring requirements are unique. New England Metal Finishing works closely with clients to develop customized deburring solutions tailored to their specific needs, including modifications to existing machinery or designing and building new systems from scratch. Process Development and Optimization: New England Metal Finishing's team of experts possesses deep knowledge and experience in deburring processes. They assist customers in developing and optimizing deburring processes to achieve the desired results, improving efficiency, and reducing costs. Consulting and Technical Support: The company provides consulting services and technical support to help customers select the most suitable deburring machinery and processes for their applications. Their experienced team offers guidance on machine setup, operation, maintenance, and troubleshooting, ensuring optimal performance and productivity. Quality Control and Inspection: New England Metal Finishing places a strong emphasis on quality control throughout the deburring process. They employ advanced inspection techniques, such as optical measurement systems and dimensional analysis, to verify the accuracy and consistency of deburring results, ensuring compliance with stringent quality standards. New England Metal Finishing, Inc. is a reputable provider of deburring machinery and services, offering innovative solutions to meet the diverse needs of its customers. With a focus on customized solutions, process development, consulting, and quality control, the company is dedicated to delivering outstanding deburring results and ensuring customer satisfaction. Whether it's through their cutting-edge machinery products or their comprehensive service capabilities, New England Metal Finishing remains committed to providing reliable, efficient, and high-quality deburring solutions for businesses across various industries.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services