Midvale Industries, Inc.

Midvale Industries, Inc.Request A Quote

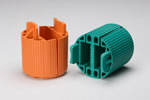

St. Louis, MOMidvale Industries, Inc. is a reputable company specializing in the design, manufacturing, and distribution of high-quality deburring machinery and comprehensive deburring solutions. With a strong commitment to excellence, innovation, and customer satisfaction, Midvale Industries has established itself as a trusted leader in the field of deburring. Deburring is a crucial process in manufacturing that involves the removal of burrs, sharp edges, and other imperfections from metal, plastic, and composite parts. Midvale Industries understands the importance of efficient and precise deburring in achieving optimal product quality, performance, and safety. Midvale Industries offers a wide range of deburring machinery that caters to the diverse needs of various industries. Their product portfolio includes vibratory deburring machines, tumble barrel deburring systems, centrifugal deburring machines, brush deburring systems, and custom-designed deburring solutions. These machines are meticulously designed and engineered to deliver consistent and precise deburring results, ensuring exceptional part quality and functionality. One of the key strengths of Midvale Industries is their dedication to innovation and technological advancements. The company invests heavily in research and development to stay at the forefront of deburring technology. Their team of experienced engineers and technicians works closely with customers to understand their specific deburring requirements and challenges. Through this collaborative approach, Midvale Industries develops customized deburring solutions that meet the highest standards of quality, efficiency, and precision. Midvale Industries' deburring machinery is known for its durability, reliability, and performance. The machines are manufactured using top-grade materials and state-of-the-art manufacturing processes, ensuring long-lasting operation even in demanding industrial environments. The company's stringent quality control procedures ensure that every machine delivers consistent and accurate deburring results, surpassing industry standards. In addition to their exceptional deburring machinery, Midvale Industries offers a comprehensive range of services to support their customers' needs. They provide installation and commissioning services, ensuring that the deburring machines are seamlessly integrated into the customers' production lines. Midvale Industries also offers comprehensive training programs to ensure that operators are well-trained in the operation and maintenance of their machinery. Additionally, their dedicated technical support team provides prompt assistance and troubleshooting, minimizing downtime and maximizing productivity. Midvale Industries takes pride in their customer-centric approach. Their knowledgeable sales and support team works closely with customers, providing expert advice and guidance throughout the entire process. The company is committed to building long-term relationships, offering exceptional customer service and support from initial consultation to after-sales assistance. In summary, Midvale Industries, Inc. is a trusted provider of deburring machinery and comprehensive deburring solutions, known for their dedication to excellence, innovation, and customer satisfaction. With their advanced technology and customization capabilities, they cater to the diverse needs of industries seeking efficient and precise deburring solutions. Midvale Industries is dedicated to helping their customers achieve superior part quality, operational efficiency, and overall success in their manufacturing processes.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services