Brandt Industries, Inc.

Brandt Industries, Inc.Request A Quote

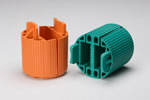

Chattanooga, TNBrandt Industries, Inc. is a leading company specializing in the design, manufacturing, and servicing of deburring machinery and equipment. With a strong commitment to innovation, quality, and customer satisfaction, Brandt Industries has established itself as a trusted name in the deburring industry. Brandt Industries offers a comprehensive range of deburring machinery designed to meet the diverse needs of various industries. Their product portfolio includes vibratory deburring machines, tumbling machines, centrifugal disc finishers, and custom-engineered deburring solutions. These machines are designed to remove burrs, sharp edges, and other surface imperfections from a wide range of materials, including metal, plastic, and composite materials. Brandt Industries' deburring machinery is known for its high-performance capabilities, precision, and reliability, ensuring exceptional results and consistent quality. One of the key strengths of Brandt Industries is their ability to provide customized deburring solutions. They understand that each customer has unique requirements and deburring challenges, and they work closely with their clients to develop tailored solutions that precisely meet their needs. With a team of experienced engineers and designers, Brandt Industries leverages their expertise to create deburring machinery that is optimized for specific applications, ensuring maximum efficiency and effectiveness. In addition to their exceptional deburring machinery, Brandt Industries provides comprehensive services to support their customers throughout the entire lifecycle of their deburring equipment. Their service capabilities include installation, commissioning, training, preventive maintenance, repairs, and spare parts supply. Brandt Industries has a team of highly skilled technicians and engineers who are dedicated to ensuring that their customers' deburring machinery operates at peak performance, minimizing downtime and maximizing productivity. Brandt Industries takes pride in delivering exceptional customer service. They are committed to building long-term relationships with their clients by providing personalized attention and support. Their team of experts collaborates closely with customers, offering technical expertise, guidance, and timely communication throughout every project. Brandt Industries' commitment to customer satisfaction has earned them a reputation for professionalism, reliability, and responsiveness. Quality is deeply ingrained in Brandt Industries' operations. They employ rigorous quality control measures throughout the manufacturing process to ensure that each deburring machine meets the highest standards of performance, durability, and reliability. By using top-quality materials, employing skilled craftsmen, and conducting thorough testing procedures, Brandt Industries delivers deburring machinery that consistently delivers excellent results and withstands demanding operating conditions. Safety is a top priority at Brandt Industries. They are dedicated to providing safe working environments for their customers. Brandt Industries' deburring machinery is designed with built-in safety features, including safety guards, interlocks, and emergency stop buttons, to ensure the protection of operators and prevent accidents. They adhere to stringent safety standards and regulations to ensure the highest level of operational safety for their customers. In summary, Brandt Industries, Inc. is a trusted provider of deburring machinery and equipment. With their diverse range of deburring products, custom engineering capabilities, comprehensive service offerings, commitment to safety and quality, and customer-centric approach, they are well-equipped to meet the unique needs of customers in the deburring industry. Brandt Industries takes pride in delivering reliable, efficient, and safe deburring machinery that enhances the quality and precision of their customers' products.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services