Arrow Cryogenics Inc.

Arrow Cryogenics Inc.Request A Quote

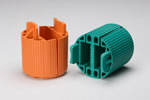

Blaine, MNArrow Cryogenics Inc. is a leading provider of advanced deburring machinery products and comprehensive cryogenic surface treatment solutions. With a strong commitment to innovation, precision, and customer satisfaction, the company has established itself as a trusted partner for businesses seeking superior deburring results and enhanced surface finishes. Deburring Machinery Products: Arrow Cryogenics offers a range of cutting-edge deburring machinery products that incorporate cryogenic technology to achieve exceptional deburring performance. These products are engineered with precision, durability, and advanced features to deliver superior deburring results. The company's deburring machinery product lineup includes: Cryogenic Deburring Machines: Arrow Cryogenics specializes in cryogenic deburring machines that utilize the power of extreme cold temperatures to remove burrs and surface imperfections. These machines employ controlled freezing and thermal shock to shrink burrs, making them brittle and easily removable. Cryogenic deburring ensures precise and consistent results, particularly for intricate parts and delicate components. Cryogenic Deflashing Equipment: The company provides cryogenic deflashing equipment that employs cryogenic temperatures to remove excess flash from molded parts. This process selectively freezes and embrittles the flash, allowing for easy removal while preserving the integrity of the finished product. Cryogenic deflashing delivers efficient and precise results, minimizing material waste and reducing post-processing time. Cryogenic Polishing Systems: Arrow Cryogenics offers cryogenic polishing systems that combine cryogenic treatment with advanced polishing techniques to achieve enhanced surface finishes. These systems use cryogenic temperatures to alter the surface structure of the material, resulting in improved smoothness, shine, and resistance to wear. Cryogenic polishing is suitable for a wide range of materials, including metals, plastics, and composites. Service Capabilities: In addition to their advanced deburring machinery products, Arrow Cryogenics provides a comprehensive range of service capabilities to support their customers' deburring needs. These capabilities include: Application Engineering: The company's team of application engineers possesses extensive knowledge and expertise in cryogenic deburring processes and applications. They work closely with customers to understand their unique deburring challenges and recommend the most suitable machinery and process parameters to achieve optimal results. Process Development and Optimization: Arrow Cryogenics collaborates with customers to develop and optimize cryogenic deburring processes. Their experts analyze factors such as part geometry, material, and desired finishes to recommend the most efficient and effective deburring methods, ensuring optimal performance and cost-effectiveness. Customized Solutions: The company specializes in providing customized deburring solutions tailored to meet specific customer requirements. They work closely with clients to understand their unique needs and develop customized machinery and processes that address their specific deburring challenges. Quality Assurance: Arrow Cryogenics maintains a strong focus on quality control throughout the deburring process. They employ advanced inspection techniques, including visual inspections, dimensional measurements, and surface analysis, to verify the accuracy and consistency of deburring results. This ensures compliance with stringent quality standards and customer specifications. Arrow Cryogenics Inc. is a trusted provider of advanced deburring machinery and cryogenic surface treatment solutions. With a focus on innovation, application engineering, process optimization, and exceptional customer support, the company is dedicated to delivering efficient, precise, and reliable deburring solutions that enhance the quality and functionality of manufactured products. Whether it's through their cutting-edge machinery products or their comprehensive service capabilities, Arrow Cryogenics remains committed to driving customer success and satisfaction in the field of deburring and surface finishing.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services