JB Stamping, Inc.

JB Stamping, Inc.Request A Quote

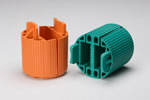

Cleveland, OHJB Stamping, Inc. is a leading provider of precision metal stamping and fabrication solutions, specializing in the production and distribution of deburring machinery products. With a commitment to quality and innovation, the company has established itself as a trusted partner for businesses seeking efficient and effective deburring solutions. Deburring Machinery Products: JB Stamping offers a comprehensive range of deburring machinery products designed to remove burrs, sharp edges, and imperfections from metal components. These products are engineered with precision and durability to deliver consistent and reliable deburring results. The company's deburring machinery product lineup includes: Belt and Disc Sanders: JB Stamping provides belt and disc sanders that utilize abrasive belts and discs to remove burrs and achieve smooth surface finishes. These machines offer versatility and precision in deburring various part sizes and shapes, making them suitable for a wide range of applications. Vibratory Tumblers: The company's vibratory tumblers use a combination of vibratory action and abrasive media to effectively remove burrs and impart a uniform finish on workpieces. These machines are ideal for deburring small to medium-sized parts with complex shapes and intricate details. Brush Deburring Machines: JB Stamping offers brush deburring machines equipped with rotating brushes made of abrasive materials. These machines are designed to remove burrs and achieve consistent surface finishes on flat and contoured surfaces. They are particularly effective for deburring larger parts with intricate geometries. Automated Deburring Systems: The company specializes in the design and integration of automated deburring systems. These systems combine robotics, advanced tooling, and process control to automate the deburring process, improving productivity, efficiency, and quality. JB Stamping works closely with customers to develop customized automated deburring solutions tailored to their specific needs. Service Capabilities: In addition to their high-quality deburring machinery products, JB Stamping offers a range of service capabilities to support their customers' deburring needs. These capabilities include: Consulting and Process Optimization: The company's team of experts provides consulting services to assist customers in selecting the most suitable deburring machinery and processes for their specific applications. They offer process optimization solutions to enhance efficiency, reduce cycle times, and improve overall deburring performance. Customization and Integration: JB Stamping understands that each customer may have unique deburring requirements. The company works closely with clients to develop customized deburring solutions, integrating the appropriate machinery into existing production lines or designing new systems tailored to specific applications. Training and Technical Support: JB Stamping offers comprehensive training programs to educate customers on the operation, maintenance, and safety aspects of their deburring machinery. Their experienced support team provides ongoing technical assistance, troubleshooting support, and timely maintenance services to ensure smooth operations and minimize downtime. Quality Assurance: The company maintains stringent quality control measures throughout the deburring process to ensure the accuracy and consistency of deburring results. They perform rigorous inspections and measurements to meet customer-specific quality standards and specifications. JB Stamping, Inc. is a trusted provider of deburring machinery and solutions, offering a comprehensive range of products and services to meet the diverse needs of their customers. With a focus on customization, process optimization, training, and quality assurance, the company is dedicated to delivering efficient, precise, and reliable deburring solutions that enhance the quality and functionality of manufactured products. Whether it's through their cutting-edge machinery products or their comprehensive service capabilities, JB Stamping remains committed to driving customer success and satisfaction in the field of deburring.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services